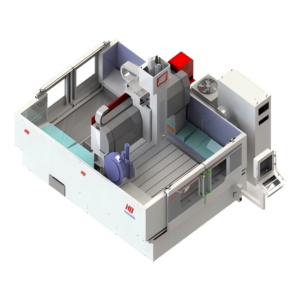

Technical parameters

| technical parameter | unit | LQS5AXX25 H/L | LQS5AXX30 H/L | LQS5AXX40 H/L |

| Workbench length | Mm | 4, 6, 10, 12 (the length of the workbench can be increased by 2 meters) | ||

| Workbench width | Mm | two thousand and one hundred | two thousand and six hundred | three thousand and six hundred |

| X-direction travel | Mm | 420062001020012200 (increase by 2 meters) | ||

| Travel in Y/Z direction | Mm | 2500 × 1500 | 3000 x 1500 | 4000 × 1500 |

| Guide rail form | X: Parallel distribution of four tracks on both sides Y: Vertical distribution of four tracks on top and bottom Z: Four roller tracks distributed in four directions | |||

| Spindle end face to workbench | Mm | 200-1700 (customizable) | ||

| Main spindle can be installed | Standard A head optional B1 head | |||

| Tool magazine capacity | Standard 20 is 1 unit (maximum of 20 digits x 4 units) | |||

| Maximum loading height | Mm | 1600 (customizable) | ||

| Maximum loading width | Mm | three thousand and one hundred | three thousand and six hundred | four thousand and six hundred |

| Rapid movement/feed rate | M/min | 30/0-15 | ||

| positioning accuracy | zero point zero one | |||

| Repetitive positioning accuracy | zero point zero zero five | |||

| External dimensions: length (excluding electrical cabinet) | Mm | 9 meters, 11 meters, 15 meters, 17 meters (increasing by 2 meters) | ||

| External dimensions: width x height (excluding electrical cabinet) | Mm | 6000 * 6500 | 6500 * 6500 | 7500 * 6500 |

| Typical configuration of CNC system | 3+2 model with Siemens 828D/Five axis linkage standard with Siemens 840Dsl | |||