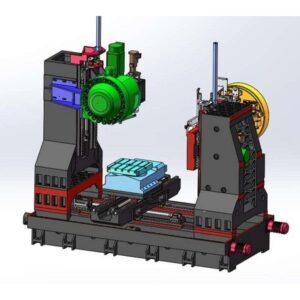

Machine Feature

- The machine is a set of milling, drilling, tapping, as one of the automatic composite processing center, suitable for processing various lengths of steel, copper, aluminum and other metal processing.

- Equipped with automatic chip removal machine.

- Adopt BT50/BT40 spindle taper hole to increase machine rigidity.

- Add machine protective cover to ensure operator safety and environmental hygiene.

- Can be equipped Adopt arm type ATC.

- Models of different specifications can be customized according to customer requirements

Machine Specification

| Item | Parameter | ||

| Machining Range | X axis travel | mm | 6000 |

| Y axis travel | mm | 700 | |

| Z axis travel | mm | 700 | |

| Distance from spindle nose to worktable | mm | 200-900 | |

| Worktable | Worktable size | mm | 700*6000 |

| Max load | T | 6 | |

| T slot qty | No. | 4 | |

| T slot size | mm | 18/120 | |

| Spindle | Driving type | 皮帶 | |

| Spindle speed | rpm | 10-6000 | |

| Main motor power | kW | 18.5 | |

| Spindle torque | N·m | 482 | |

| Spindle taper | ISO7:24NO50 | ||

| Spindle pull riviet | P50T-2-MAS403 | ||

| Spindle size | mm | Φ155 | |

| Three axes motor | X、Y、Z servo motor torque | N·m | 28/18/18 |

| X、Y、Z servo motor speed | rpm | 2000 | |

| Min step | mm | 0.001 | |

| Feeding rate | X、Y、Z axis feeding speed | mm/min | 2010/10/10 |

| X、Y、Z axis rapid speed | mm/min | 20/20/15 | |

| ATC | Tools qty | No. | 24 |

| ATC type | Arm type | ||

| Machine Weight | T | 26 | |

| Overall size | mm | 9000*3200*3000 | |

| Guide rail | P level precision | mm | X/Y/Z axis spec:45/65/55 |

| Lead screw | C level precision | mm | X/Y/Z spec:Φ63/Φ50/Φ40 |

| Precision standard JIS | |||

| Positioning precision | X/Y/Z three axes | mm | ±0.015/ full length |

| Repeated positioning precision | X/Y/Z three axes | mm | ±0.01/full length |