BASIC INFORMATION

- The machine integrates the function of milling, drilling and tapping

- Machining for various materials with special shape and curved surface, such as aluminum, steel, copper.

- Widely used in automotive industries for machining bumpers, sunroof rail, rack and etc.

TECHNICAL DATA

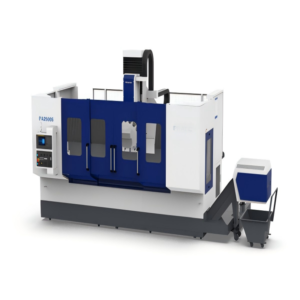

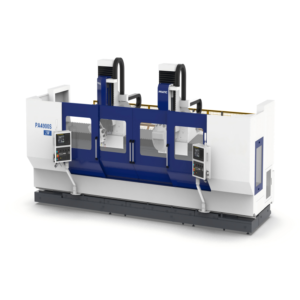

| Items | Unit | PDE4D-CNC2500 | PDE4D-CNC4500 | PDE4D-CNC6500 | |

| Travel | X-axis | mm | 2500 | 4500 | 6500 |

| Y-axis | mm | 500 | |||

| Z-axis | mm | 700 | |||

| B-axis | / | ±90° | |||

| Distance from spindle nose to table surface | mm | 130-830 | |||

| Worktable | Size (length*width) | mm | 2500×550 | 4500×550 | 6500×550 |

| Max. load | kg/m2 | 1000 | |||

| T-slot (Number/width/center distance) | mm | 5/18/100 | |||

| Spindle | Type | / | Motorized | ||

| Rated power | kW | 15/16 | |||

| Max. speed | rpm | 18000 | |||

| Taper | / | BBT/SK/CAT40 | |||

| Feedrates | Rapid on X/Y/Z | m/min | 60/28/28 | ||

| X/Y/Z Cutting Feed Rate | m/min | 15 | |||

| Tool Magazine | Type | / | Disc type | ||

| Capacity | pcs. | 24 | |||

| Tool-to-tool time | sec | 2 | |||

| Dimension | Machine Height | mm | 3200 | ||

| Covering Area | mm | 6700*2850 | 8710*2850 | 10700*2850 | |

| Machine Weight | kg | 10500 | 12500 | 14700 | |

.21.png)